Activites

- Pipeline Laying

- Station Piping & Plant maintenance

- Erection & Maintenance of Tank, Vessel, Boilers …

- Commissioning & Pre commissioning activities

- Procurement

- Quality Assurance & Control

- Civil, Structural & Steel Work

- Permanent /Temporary Cathodic Protection

- Electrical and Instrumentation

- Telecom & SCADA

Pipeline Laying

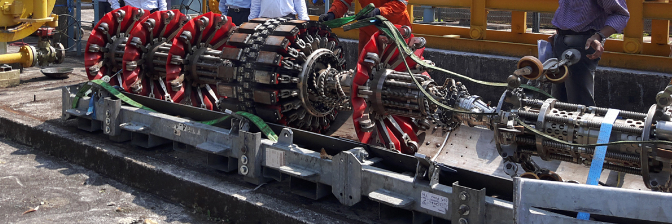

In brief pipeline laying activity includes supply of bulk materials (other than free issue from our clients), pipe laying work including but not limited to Construction Management, HSE & Quality Management, Survey, clearing of ROU, grading. Stringing, bending, welding, trenching, lowering, crossings. Tie-ins, NDT and destructive testing, backfilling, laying of HDPE ducts (wherever required), site restoration, hydrotesting, dewatering, drying, pre-commissioning, commissioning and Gas in of pipelines of various sizes including construction / installation of related facilities like SV stations, tap-off station at various locations.Station Piping & Plant maintenance

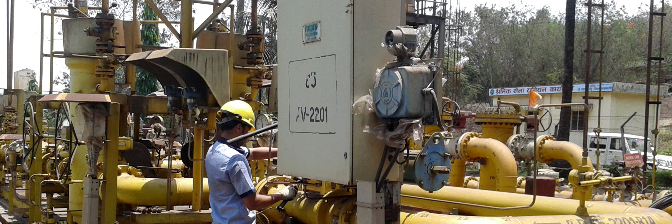

Station Piping & Plant maintenance includes the Fabrication, erection, NDT, Hydro Testing, cleaning by card board blasting/air blowing , box-up of new/existing piping, installation of valves, control valves, on-line instruments ( either welded or flanged) , including steam line (coming under the preview of IBR as per clients requirement ),Pneumatic test of flare lines ... Approval from IBR authority if necessary. MAS will also supply the required tools, tackles, machinery, resources, consumables, water & air for performance of the activities as per site conditions.Erection & Maintenance of Tank, Vessel, Boilers …

In brief this includes all related activities for the Erection & Maintenance of Tank, Vessel, Boilers …Commissioning & Pre commissioning activities

MAS CONSTRUCTIONS - shall engage a specialist agency to act as an interface between construction and operations and which will be primarily responsible for developing operating norms & procedures and pre-commissioning / commissioning activities. Manned by experienced specialists in different areas, the subcontractor shall render supervisory commissioning assistance to MAS CONSTRUCTIONS.The Operation & Commissioning subcontractor nominated for this job will also review Process & Engg documents with respect to operation & safety.

Thereafter, at the appropriate stage Commissioning subcontractor will be involved for preparation of Operation & Control Manual as well as for all the necessary activities of pre-commissioning & commissioning.

Procurement

MAS CONSTRUCTIONS - shall set up fully operational project offices at various sites which shall have a large professional workforce to manage the project purchase activities – normally through an experienced procurement coordinator. Besides MAS CONSTRUCTIONS has the large data bank of indigenous and international vendors providing wealth of information available to clients. MAS CONSTRUCTIONS shall also tie up to a Third Party Inspection Agency which shall have a large network of Inspection Offices in India and abroad for providing inspection and expediting services to clients. Also, Procurement Division has a separate department which provides efficient and expert services to clients in the critical areas of Custom Clearance and Transportation (C & T).The material in the scope of MAS CONSTRUCTIONS will be procured through designated purchase manager. After the placement of order, coordinators for expediting and C & T will provide necessary follow up till delivery at site.

Quality Assurance & Control

MAS CONSTRUCTIONS and his sub-contractors shall operate a quality system satisfying the applicable provisions of BS 5750 / ISO 9000 (Series) latest edition and shall execute the total work as per applicable codes listed in Basic design report.Civil, Structural & Steel Work

The various civil drawings will be developed based on good engineering practice and it shall be as per the Indian standards. Minimum Inter distances between various facilities will be taken care of for developing the Overall plot plan. Design of foundation, footings,Columns, beams, slabs etc will be carried out with the aid of suitable software and the results must be submitted to client for the review.Site grading, cutting of trees (if required) including stripping and clearing of expansion area, cutting, earthwork in filling with approved non-expansive soil from borrow earth, transportation, spreading of earth in layers, watering, rolling, disposal of surplus /unserviceable earth all complete as per standards, specifications, drawings, documents and direction of client.

Construction of RCC Foundation for equipment, RCC pavement, RCC sleepers including earthwork in excavation in all types of soils including soft rock, providing and laying reinforcement steel, backfilling with excavated/ borrow good earth, disposal of surplus/unserviceable earth beyond plant boundary limit, transportation including supply of all other related materials as required all complete as per standards, specifications, drawings, documents and direction of client.

Providing Chain link fencing including grouting steels posts, painting of steels members,earth work in excavation, backfilling with excavated/ borrow good earth for PCC columns/footings, disposal of surplus/ unserviceable material, transportation of materials including supply of all related material etc., all complete as per standards, specifications, drawings and direction of client.

Collection of debris, surplus/ unserviceable earth and disposal of same outside the plant boundary limit including transportation, loading, unloading, clearing of site etc. all complete as per specifications and direction of client.

Earthwork in excavation in all types of soils at all depths including de-watering below ground level. Backfilling with available good soil as well as from approved borrow areas at all depths and disposal of surplus earth, debris and rock material to the area designated by the client. Sand filling/Murrum/Sand Gravel mix in plinth and below footings/foundations. PCC works below foundations/columns of chain link fencing, Skid etc. RCC work in all types of foundations, sub structure for various types of structures, Equipment, etc. at all depth & heights including centering, shuttering providing insert plates and anchor bolts, embedded sleeves etc. at different stages of concreting. Preparation of Bar Bending Schedule. Dismantling/Demolishing of PCC/RCC, Brickwork, Structural Steel, etc. for all depths below plinth level and all heights above plinth level.

Permanent /Temporary Cathodic Protection

Cathodic Protection System for the pipeline system shall be engineered and provided. The scope shall include the temporary cathodic protection system (as covered in the basic design report) to protect the pipeline from external corrosion during the construction phase.Electrical and Instrumentation

Electrical and Instrumentation consist of supply of instrument items (as per schedule of quantities/rates and SCC), instruments, their erection, testing, calibration and commissioning and making it ready for commercial operation.Insulating joints for electrical isolation of the pipeline with the plant piping and over ground pipeline shall be installed as per detailed design and provision of codes.